Originally Posted by

Goldsmith

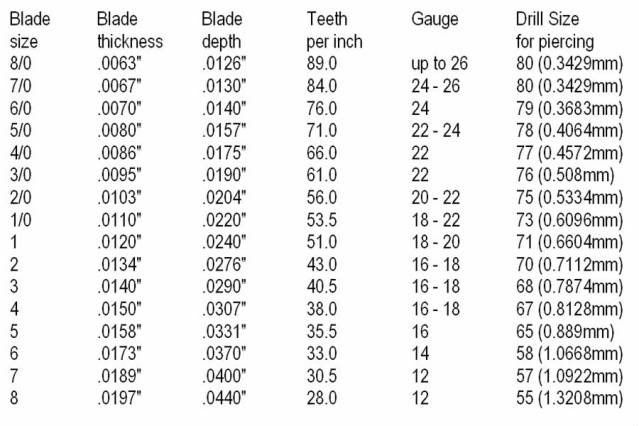

Pat, the sizes of piercing saw blades can be confusing, for easy reference, Grade 8/0 is the smallest, then the saws get larger as the numbers decrease up to Grade 0 or as some call it 1/0. In the past saw blades were numbered on their packets with just zeros, such as 0-00-000-0000-00000-000000 and onwards, these sizes refer to 1/0-2/0-3/0-4/0-5/0-and 6/0.

( I use 6/0-4/0-3/0-2/0-0 ) Then after size 0, the blades get larger and they change the size references to single numbers such as Grades 1-2-3. I have rarely used a saw blade larger than Grade 2. unless piercing thicker plastics or wood. For most jobs I use sizes 2/0,3/0 and4/0, usually for piercing metals 0.4mm. up to 1.5mm. thick.

I hope this makes sense:-)

James

Reply With Quote

Reply With Quote

Bookmarks