Once all the wiring was complete, the base is bolted back on, and the pneumatic pipes connected.

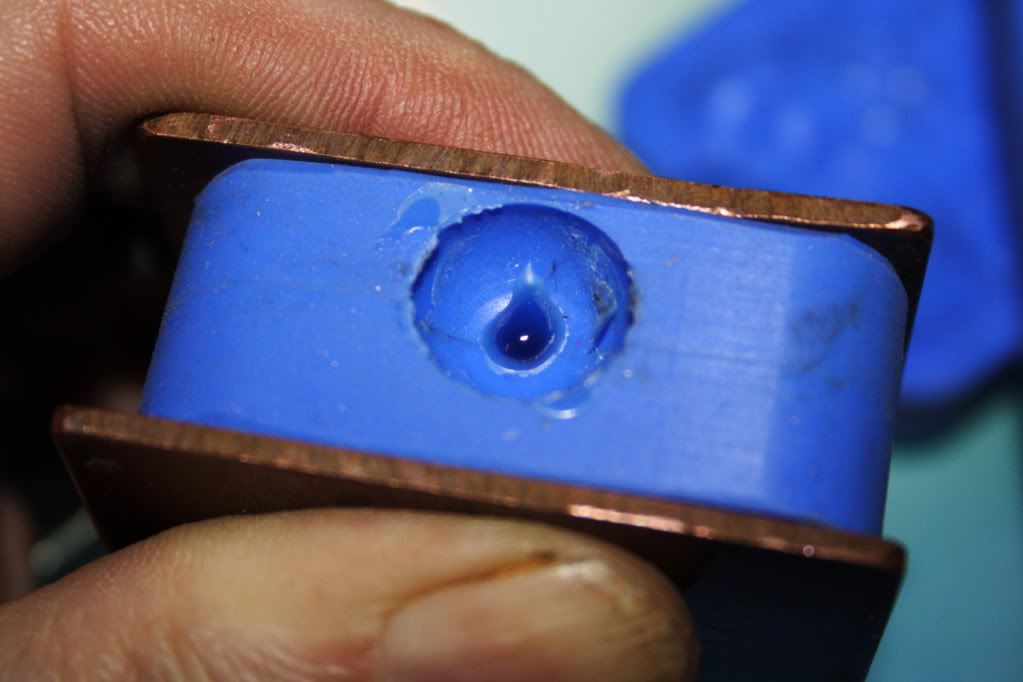

A couple of turns of PTFE tape seal the threads around the wax injector nozzle and temperature gauge.

First run - up to temperature and holding fine at just below 65 deg C.

And pressure holding at 12.5 PSI, ready for some tests!

Reply With Quote

Reply With Quote

Bookmarks