My wax injector blew up on Friday. It just went off, and refused to heat up the wax.

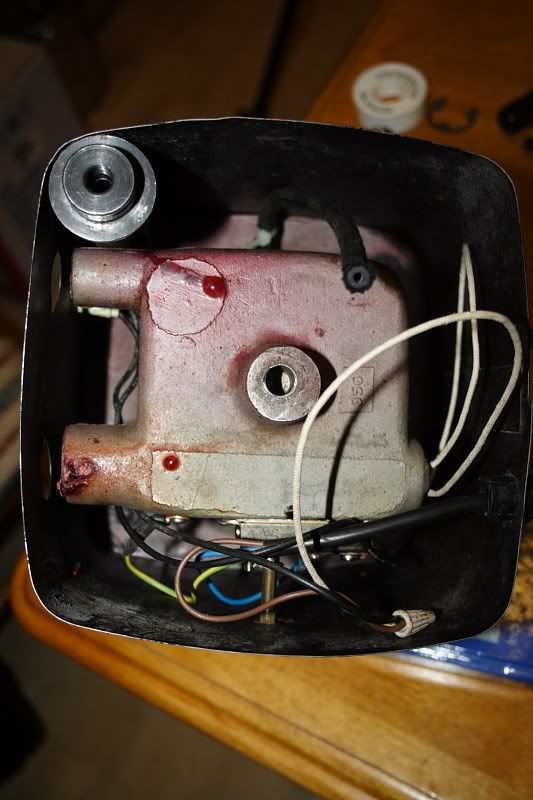

So I dismantled it to look for the problem.

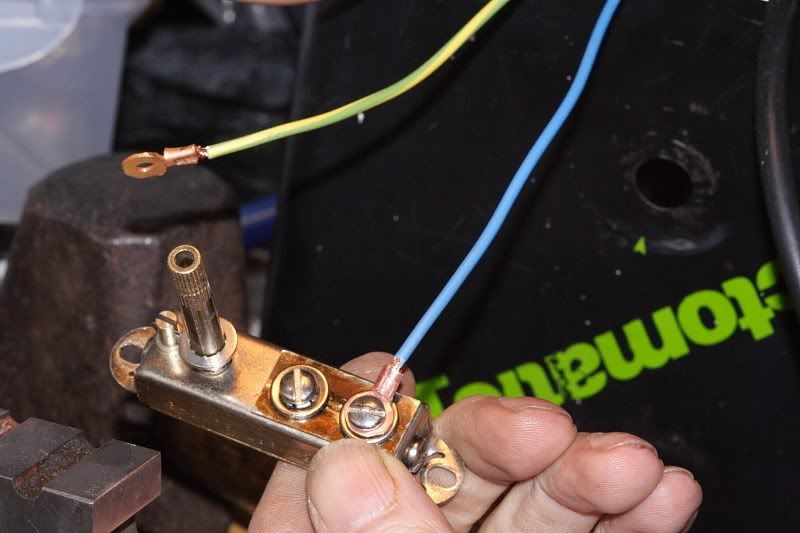

I bought it as a UK spec wax injector from a guy in the states on eBay and I've used it for about a year with no problems until now. - The problem turned out to be the heater (the slim cylinder with two white wires which looks a bit like a detonator).

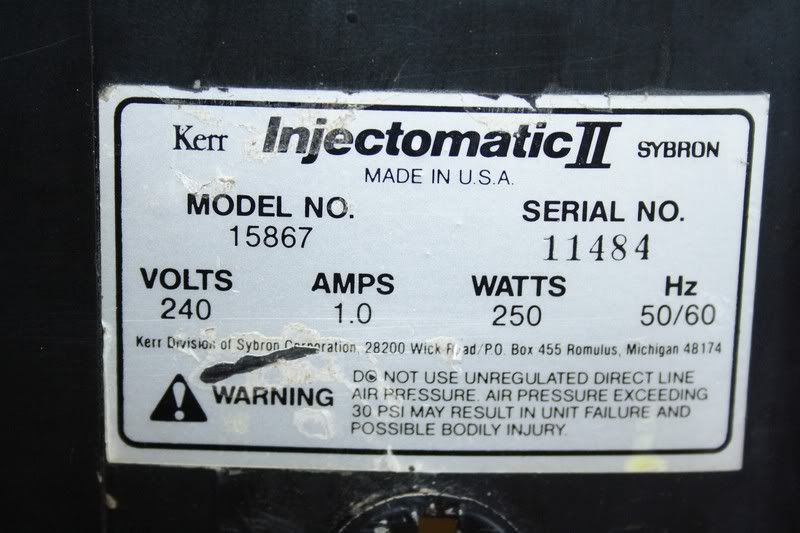

The spec is clearly UK 240V

But the cartridge heater has at some time been 'upgraded' to the US 120V version, which - not unreasonably, gave up when used at the higher voltage of 240V here in the UK. - it would have been nice of the seller to mention it!

Ho - Hum . . Caveat emptor and all that - Still - could be worse, I've found a 240V replacement made by the original equipment manufacturer Hotwatt from is stocked by RS components at a very reasonable 17 quid, so I should have it back together by next weekend.

Reply With Quote

Reply With Quote

Bookmarks